Examples of Coating Services

Cetry helps medical device manufacturers and their suppliers by means of problem solving, process modelling, characterization of product properties, device and materials qualification, process and manufacturing validation, related regulatory issues, quality assurance, and design and build of specialized equipment. Here follow some examples of coating-related services provided by Cetry.

List of Examples:

Related Pages

Refer to examples of problem solving, modelling and characterization to find out about coating-related problem solving for various customers.

Refer to equipment building and design in order to find out about our experience with specialized coating equipment.

Refer to examples of coating development to find out about recipe building.

Refer to the services page for other Cetry activities.

Repair of a UV-curable coating for PTCA

| • Client: | Major European manufacturer of PTCA balloon catheters |

| • Subject: | Quality fluctuation of a UV-curable coating |

The client requested investigation into a manufacturing method that would improve the quality of their existing UV-curable hydrogel coating. At the time, their coating showed undesired fluctuation of internal strength and adhesion, albeit within safety boundaries. A study was performed on the material properties, manufacturing methods, coating properties, etc. in order to tackle the problem. A solution was found and the results were intensively tested, both in vitro and in vivo. The latter definitely showed that the coating quality was stabilized at the high end of the scale, i.e. with the best performance. The manufacturing upgrade could be done in compliance with the existing CE-registration. Cetry also supplied supporting technical documents as well as background information. Most of the upgrade was obtained by putting the whole coating system into a mathematical model - think of application mechanics, drying curves, curing chemistry, and so on.

return to top...

Introduction of QC testing for coating solutions

| • Client: | Manufacturer of diagnostic catheters |

| • Subject: | QC testing of coating solutions |

It was requested to provide quality control methods for various coating solutions that were made by the client's chemistry lab. Each solution consisted of various sorts of polymers and salts. The main question was: How can we detect whether a coating solution was prepared correctly or not? The lab was well equipped with all sorts of analyzers, which made it easy to start. Most chemical compounds showed unique fingerprints under infra-red or ultraviolet. One of the salts proved to be tricky - only trace amounts were used. None of the available analytical techniques were able to detect these small amounts, so that a new method was developed by Cetry. This new technique proved to be very capable of detecting the salt. The whole set of quality control tests was successively validated, with protocols provided by Cetry and implemented by the people who would have to work with the new Quality Control methods. Protocols and results were inspected and approved by the client's quality assurance unit. The tests then became standard (within the company) for this matrix of coating solutions.

return to top...

Aging and testing of particulate matter relating to hydrogel coatings

| • Client: | Major manufacturer of PTA and PTCA balloon catheters |

| • Subject: | Long-term integrity testing of hydrogel coatings |

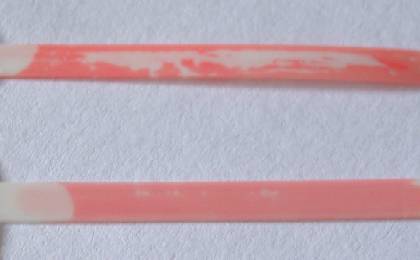

Hydrogel coatings have the tendency to age poorly when too much internal stress build-up occurs across the layer. This stress induces a force between the coating and the underlying substrate (the catheter), so that the coating may detach in the long run. A hydrogel coating should thus be evaluated on stress-related chipping during aging and after sterilization. The client's request was to perform such aging program, including simulated in-use tests that would reveal change of coating integrity in general. The coating turned out to be fine. Reports were filed and methods were justified (in-method validation). The requirements regarding particulate matter as set in both the European and the United States Pharmacopeia (EP and USP) were nicely met. The photograph at the top of this page shows what a hydrogel coating may look like after wear and aging. The strip at the bottom of the photograph represents the hydrogel coating before testing, but after staining with Congo Red (the coating itself is colorless and transparent). The strip at the top shows the same coating with stress-induced damage.

return to top...

Surface treatment of an IOL accessory for improved coating performance

| • Client: | IOL developer and manufacturer |

| • Subject: | Surface treatment for coating adhesion research |

Coating adhesion can be improved by means of RF plasma treatment. Many companies that work with polymer-based medical devices and accessories own some form of plasma equipment. The equipment is most often used for regular manufacturing and thus generally off-limits to research projects. A client, manufacturer of intraocular lenses (IOL), therefore asked Cetry to do the plasma treatments for them, so that the equipment at their own plant would not run the risk of disqualification on grounds of unknown side-effects. Next-day-delivery of the postal service made return time acceptable for speedy research. The involved engineer first checked on possible averse effects caused by packaging and transportation, which turned out to be fine, and then progressed with the actual research.

return to top...

Surface treatment of diagnostic catheters

| • Client: | Minor manufacturer of diagnostic and guiding catheters |

| • Subject: | Surface treatments |

The client ran a research program with the aim of finding optimized surface properties. A vast range of surface types had been identified, and tests would include type-representative coatings and surface treatments, including references. Cetry was requested to deliver a couple of those surface treatments, applied to several types of diagnostic catheters. Two methods involved RF plasma treatment.

return to top...

Coating integrity assessment

| • Client: | Minor manufacturer of PTA and PTCA balloon catheters |

| • Subject: | Independent coating integrity assessment |

A manufacturer of PTA and PTCA balloon catheters sought second opinion about a hydrogel coating that was offered to them by a specialized coating company. The latter was specialized in synthesizing and selling the materials, but they did not have experience with clinical applications of PTA and PTCA balloon catheters and the related safety regulations. The coating was evaluated by Cetry and results were reported. This then helped the client to make a well-balanced decision on how to cope with this coating offer.

return to top...

Specification of a coating design route

| • Client: | New start-up enterprise of a world-leading polymer manufacturer |

| • Subject: | Specification of a coating design and development route |

Starting a new enterprise for the development and manufacture of medical coatings, one of the world's leading polymer manufacturers had begun gathering information and expertise on how to do that. Cetry was asked to help define the route. The major part of the information package delivered by Cetry included (1) specifications of the coating properties (depending on clinical application) and (2) specifications of the regulatory requirements and quality assurance. Notes were included regarding development, testing, clinical issues, etc. The information package was first sent to them and later on discussed on-site, so that unfamiliar passages could be explained.

return to top...

Independent party during coating risk assessment session

| • Client: | Major European manufacturer of diagnostic catheters and stent delivery systems |

| • Subject: | Risk Assessment regarding application of new medical devices |

CE registration requires comprehensive risk analysis of the new product. The assessments should be based on tests, models, expertise, etc. This means that sometimes external expertise is hired to assess the risks related to certain aspects of the product and its use. Physicians are often interviewed regarding clinical effects, biochemists are hired to look into biological issues, etc. Cetry has been hired several times to sit in on a product risk analysis, mainly to provide input regarding surface-related effects. Think of particle generation by coatings, thrombogenicity of surfaces and loss of functionality.

return to top...

Equipment repair

| • Client: | IOL manufacturer / Manufacturer catheters and stents for cardiology and radiology |

| • Subject: | Repair of production plasma unit |

Cetry was requested to repair a faulty operating gas-discharge unit. Down-time of the equipment had accumulated to an unacceptable level (stagnation of production had already occurred) and their own engineers were not able to find and solve the problem fast enough. Aided by the engineers, Cetry was able to locate the fault and even repair it with available spare parts. The equipment was tested and proved to work as intended. Production was regained. This is an example where the client realized that costs of hiring a specialist would be negligible compared to the damage done by production interruption. A similar situation occurred for another client. Multiple faults in the equipment were identified that directly compromised production consistency. The client was now able to correct the equipment, upgrade maintenance and improve manufacturing yield.

return to top...

Drying of coating material

| • Client: | Manufacturer of biodegradable coating materials |

| • Subject: | Drying of coating material |

The client had problems removing all solvent from a certain coating material, after its synthesis. Air drying, vacuum drying, etc. took away most of the solvent, but too high trace amounts still remained. One of their customers complained about this level, in the light of regulatory compliance. Looking into the matter, Cetry postulated that adhesion of the solvent to the coating material occurs at several energy levels. Think of weak random adhesion versus strong localized adhesion due to incorporation of solvent molecules into a crystalline structure. The latter effect requires more than vacuum or elevated temperatures to get rid of the solvent. A two-stage method was devised in order to bring residual levels down: (1) interchange of molecules, (2) break-down of crystalline structures without damaging the polymer (no scission, no oxidation). The method worked as intended, as was proven by extensive analyses.

return to top...