Note concerning Staining of Hydrogels

(by J.J.G. Bos)

Related topic:

Hydrogel Coatings

Hydrogel coatings can be made visible by submerging them in a dye such as Toluidine Blue O, Congo Red, etc. When lucky, the dye adheres to the hydrogel molecules so that a nice color remains after washing the coating.

With the coating made visible, it has become easy to inspect the film on matters such as homogeneous coverage, cracks, and particle generation.

Sometimes, however, impact of the dye proves to be disastrous. Adhesion of the dye molecules may lead to increased crosslinking within the hydrogel, which in turn may cause stress-induced particle generation (stress-cracking). The coating chips off in thousands of pieces. If not today, then tomorrow. Especially coatings based on Polyvinyl alcohol (PVA) tend to suffer from this phenomenon when stained with Congo Red.

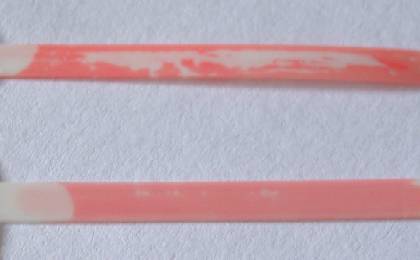

The above picture shows the impact of Congo Red staining on a PVA-based hydrogel. The lower sample was tested on wear resistance prior to staining. Although some wear is visible, the overall result is quite good (the test was somewhat rough). The upper sample was wear tested after staining with Congo Red. Coating parts easily chipped off. The sharp edges along the stripped area indicate stress-cracking. Apparently, Congo Red induced lots of additional stress in this particular coating and made it crack up easily. In this case, a wear-resistant coating became wear sensitive due to staining.

Selecting a dye for purpose of coating staining should thus include an impact assessment, in order to prevent undesired side-effects to pop up during the characterization effort. One must always consider when staining is appropriate: prior to or after certain manipulations, such as artificial wear, aging, particle testing, etc.

return to top...

|